Why should you select G2MT Labs for ASTM A262 intergranular corrosion (intergranular attack) testing?

- We provide accurate, repeatable results along with world-class customer service.

- We offer ASTM A262 testing from Houston for customers around the world; with overnight shipping, we can start tomorrow.

- We work with you to select the right method for your steel grade, and then deliver clear results in a reasonable time and budget.

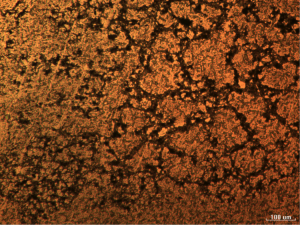

In metallography, intergranular corrosion shows up under the optical microscope as black lines around the grain boundaries (with the proper etchant).

Austenitic stainless steels are susceptible to intergranular corrosion when their heat treatment is performed incorrectly. In general, intergranular corrosion occurs as a result of precipitation of nitrides, carbides, and other inter-metallic phases, such as sigma phase, that occurs along the grain boundaries. If materials with incorrect heat treatment enter service, they are liable to crack or fail by intergranular corrosion much more rapidly than properly treated materials; ASTM A262 is a screening test to help find batches that are incorrectly processed.

Should you start with A262 Practice A, the rapid screening method?

ASTM A262 Practice A is an oxalic acid is the rapid (4 hour) screening method, often used as a first pass to determine the susceptibility to intergranular corrosion. Classification of the structure after A262 Practice A analysis will determine if the material is acceptable or if additional testing is required. If you are not sure if you need this step, please contact us for assistance.

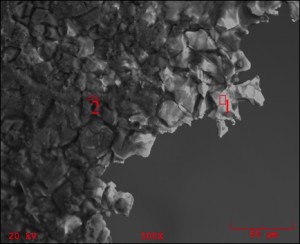

In SEM analysis, intergranular corrosion is clear by the dark lines where the grain boundaries are eaten away.

How do you select the right ASTM corrosion testing method for your material?

In everyday applications, corrosion varies by materials and solutions. For example, in highly oxidizing solutions, intergranular attack can occur due to intermetallic phases, while attack of carbides may occur somewhat less oxidizing solutions. Due to the variance of attack in different materials, numerous methods (Practices B-F) have been developed to asses

The ASTM A262 tests can determine if the proper heat treatment was performed or if the alloys are in danger of intergranular corrosion occurring in use. These tests are often run as a qualification test to ensure each batch of stainless steel is properly prepared. Each ASTM A262 Practice specification includes a list of the grades of stainless steels and the acceptable etch structures for the specific alloys. For example, many low-carbon and stabilized stainless steels (e.g. 304L, 316L, 317L, and 347) must be subjected to a sensitizing heat treatment prior to testing by the oxalic acid etch test (Practice A).

Practice A, the oxalic acid etch test is used as a rapid technique to screen samples of certain stainless steel grades to ensure they are free of susceptibility to intergranular attack. The test is generally performed for acceptance of materials, but not sufficient for rejection of materials.

ASTM A262 Practice B – “The Streicher Test” Ferric Sulfate – Sulfuric Acid

Practice B, also known as the Streicher test, uses weight loss analysis to provide a quantitative measure of the materials performance. This practice includes boiling the sample for 24 to 120 hours in the solution above, and measures the materials performance quantitatively. It is typically used for stainless alloys such as 321 and 347, Cr-Ni-Mo stainless alloys, and nickel alloys to evaluate the intergranular attack associated with the precipitation of chromium carbides at grain boundaries.

In Practice C, the Huey Test, samples are boiled for five 48-hour periods in a 65% Nitric Acid solution. The weight loss is calculated after each step, and reveals if the sample has been properly heat-treated. Please specify the maximum allowable corrosion rate and any available data on the sensitizing heat treatment performed. The Huey test works well to analyze chromium depleted regions and intermetallic precipitates, such as sigma phase, and is also used for materials in strongly oxidizing environments such as nitric acid

Practice E, the Strauss test, is performed to assess attack associated with chromium-rich carbide formation. The sample is boiled in a Cu-Copper Sulfate mixture and then bent 180° over an equal diameter bend. The test uses a visual inspection of the surface of the bent specimen to determine pass or fail.

Practice F, is a weight-loss based analysis that provides a quantitative measure of the materials performance, and is commonly used to analyzed as-received stainless steels.

Where can I get ASTM A262 corrosion testing performed?

G2MT Labs is proud to provide all of the above ASTM A262 corrosion testing, as well as the expertise to help you determine which tests to use, what to do if a test fails, and other metallurgical assistance as needed.